DLBA COMMERCIAL NEWS

DLBA & Leidos Combination: Optimized Composite Structures

FEBRUARY 18, 2022

The combination of the DLBA and Leidos structural engineering capabilities brings significant benefit to our customers and their programs. The Leidos team brings additional composite engineering capability (2 composite structural engineers and a composite manufacturing engineer, formerly of Gurit (USA) Inc.).

Seahawk Participating in U.S. Pacific Fleet’s Unmanned Systems Integrated Battle Problem

Courtesy: Chief Mass Communication Specialist Shannon Renfroe

The team has significant experience in high end, advanced marine vessels and carbon and e-glass prepreg and infusion composite construction. The team focuses on high-speed naval vessel design and analysis and has significant experience in the design and analysis of production motor yachts, racing yachts and custom super yachts to accurately predict their structural performance.

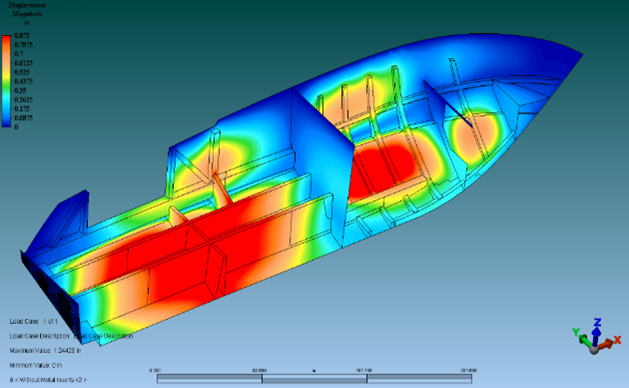

Full hull FEA of high-speed center console

Courtesy: DLBA

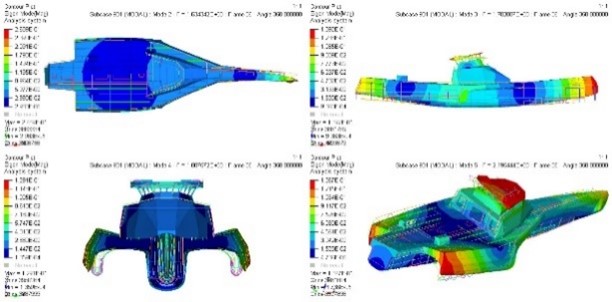

Analyses include designs of classed vessels to American Bureau of Shipping (ABS), Det Norske Veritas (DNV), Lloyd’s Register and International Organization for Standardization (ISO). On the military side, Sea Hunter and Seahawk are advanced wave piercing trimarans, designed to ABS High-Speed Naval Craft (HSNC). They were analyzed using the teams advanced Finite Element Analysis (FEA) design capability (Altair HyperWorks software suite) using ply-based modelling to create and analyze a whole vessel model.

Hard top modal analysis

Courtesy: DLBA

Modal analysis results of preliminary conceptual composite vessel design

Courtesy: Leidos

Share this article online:

HOW CAN WE HELP YOU?

FEEL FREE TO CONTACT US

DLBA Naval Architects

860 Greenbrier Circle, Suite 201 Chesapeake, Virginia 23320 USA

Phone: 757-545-3700 | Fax: 757-545-8227 | dlba@gibbscox.com

STAY UPDATED

SIGN UP FOR OUR NEWSLETTER

Keep your finger on the pulse of the latest points of focus in naval architecture and engineering: subscribe to DLBA’s concise monthly newsletter. Within it, we briefly describe and picture our latest projects and concepts. We encourage feedback and seek to have our newsletter spark conversation regarding potential collaborations and further advancements as we share our passion for the industry.