DLBA UNIVERSITY

An Experimental Study of a High Performance Tunnel Hull Craft

APRIL 13, 2021

By

K. H.Harbaugh, Visitor. Naval Ship Researchand Development Center, Langley Field, Virginia

D. L. Blount, Associate Member, Naval Ship Engineering Center. Norfolk. Virginia

Back in 2018 we added Donald Blount’s paper on the Design of Propeller Tunnels for High Speed Craft to our online library. Based on the interest received on this paper, we conclude that it remains a hot topic. Given this intel, it seems appropriate to dig a little deeper into the topic. Much of the information in that paper came from knowledge gained doing research for the US Navy. This SNAME paper by Harbaugh and Blount captures and describes the experimental results obtained in that study. It’s neat to see the theoretical efficiency gains that can be achieved by minimizing tip clearance of the propeller in the tunnel, which matches theory very well. In practice though, we have found that executing small tip clearance setups to be problematic with regard to propeller vibrations. Such a shame…..

ABSTRACT

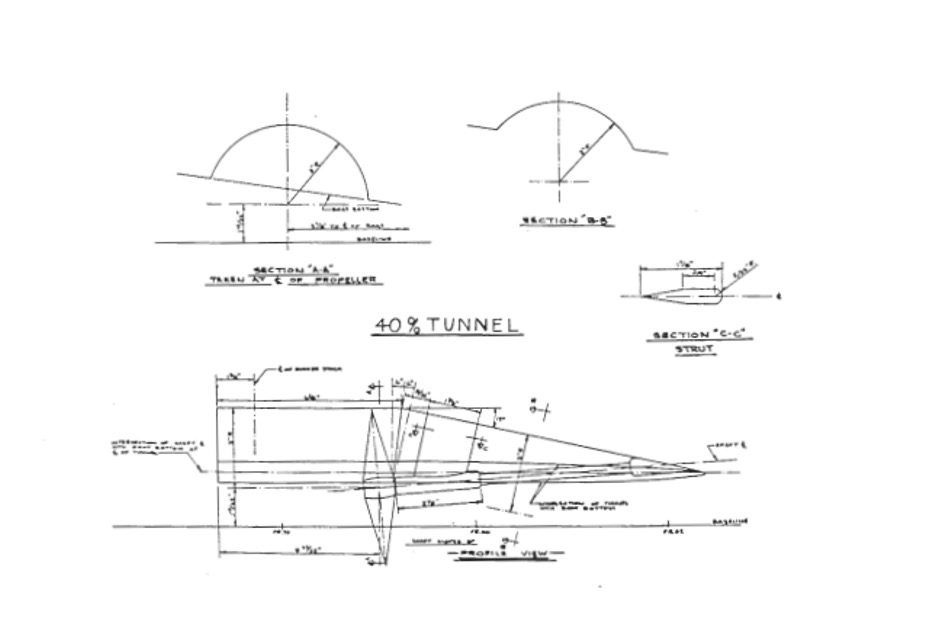

Model resistance and self propulsion data are presented from experiments on Model 5048 modified for shallow and deep tunnels and with propellers of two different diameters. Comparisons are made with data previously obtained for the same model without tunnels, and the tunnel configurations are evaluated by means of an efficiency factor. The deep tunnelled hull in combination with propellers of large diameter and the smallest permissible tip clearance com- pares performance-wise to the hull with no tunnels. A format and sufficient dimensionless coefficients are provided for horsepower estimates for alternate hull designs. Because the navigational draft requirements for the tunnel hull are much less than those without tunnels, the tunnel hull is considered to be highly desirable.

Conclusions

Through the application of an efficiency factor derived for this paper to relate the various design factors, the best performance was achieved with the deep tunnels in combination with the propellers of maximum diameter. This performance was comparable to the conventional shafting arrangement showing that the tunnel hull propulsion arrangement can be competitive in terms of propulsive efficiency. A large improvement in the navigational draft can be expected through the use of the deep tunnels. The draft of the deep tunnelled hull was 36 percent less than the hull with no tunnels. Although there were no visual signs of flow separation at model speeds, this does not imply that there will be none at full scale speeds. Further flow studies should be made at either full scale speeds or at equivalent cavitation numbers in a variable pressure water tunnel.

If you would like to receive the full paper or discuss this subject, please contact Jeffrey Bowles.

Share this article online:

HOW CAN WE HELP YOU?

FEEL FREE TO CONTACT US

DLBA Naval Architects

860 Greenbrier Circle, Suite 201 Chesapeake, Virginia 23320 USA

Phone: 757-545-3700 | Fax: 757-545-8227 | dlba@gibbscox.com

STAY UPDATED

SIGN UP FOR OUR NEWSLETTER

Keep your finger on the pulse of the latest points of focus in naval architecture and engineering: subscribe to DLBA’s concise monthly newsletter. Within it, we briefly describe and picture our latest projects and concepts. We encourage feedback and seek to have our newsletter spark conversation regarding potential collaborations and further advancements as we share our passion for the industry.