DLBA UNIVERSITY

"An Evaluation of a Resistance"

By Joseph Messler, EIT

NOVEMBER 19, 2021

Our Thoughts on This Paper

Our community has come a long way with the prediction of resistance and trim of high-speed planing craft since their evolution around WWII. We started with model tests to collect data which could be expanded using Froude scaling. Once the community amassed enough data, it was studied extensively and used to develop analytical prediction methods based on basic physics principles, model test observations and data regressions with some of the most notable work in this area being completed by Don Blount & Daniel Savitsky. These approaches became the status quo for many years until the world of computing, which created the opportunity for numerical simulations through the use of Computational Fluid Dynamics (CFD). The industry has come a long way with the application of CFD in the last 20 years. Whereas, CFD was originally best suited for comparison of alternatives of a validated hull via model test or full scale test results, the tools and operators today have the ability to make accurate predictions without the reliance on craft-specific validation data.

Today we find ourselves in the middle of the 4th Industrial Revolution (4IR), bringing the power of Artificial Intelligence (AI) into our toolkits. Given this evolution, researchers have used Artificial Neural Networks (ANNs) to develop highly accurate regression equations for the prediction of resistance and trim of planing craft, using an extremely wide range of model test data collected over the last 50 years. This new tool available to the industry is highly accurate and requires significantly less computing power than CFD. If you predict resistance and trim, you should see what Joe Messler of DLBA had to say recently about these new predictions methods at the 2021 ASNE MACC conference.

If you are an ASNE member, you can see the full presentation here.

DLBA image

Abstract

AN EVALUATION OF A RESISTANCE AND TRIM MATHEMATICAL MODEL DEVELOPED BY ARTIFICIAL NEURAL NETWORKS

By Joseph Messler, EIT, Gibbs & Cox, Inc.

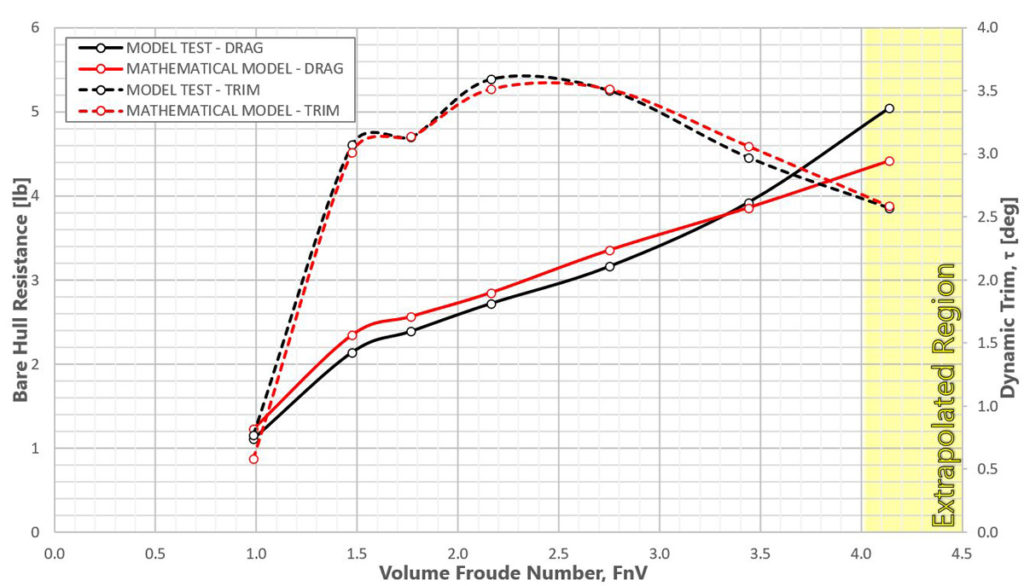

This presentation will review the application of a mathematical model developed by Artificial Neural Networks (ANN) for prediction of calm water resistance and trim. ANNs, utilizing a database of Series 62 models, smoothly fit model test data allowing for better accuracy compared to traditional regression methods and data expansion/interpolation routines. This method dependently calculates resistance and trim such that the hydrodynamic effects of one component influences the other.

Current methods for resistance and trim prediction such as CFD require considerable setup time and come at a significant computational cost. The mathematical model introduced in this presentation requires only seven inputs involving geometric and fluid characteristics. In addition, computational time is nearly non-existent. The method provides predictions of similar or better accuracy to more advanced programs without the computational expense.

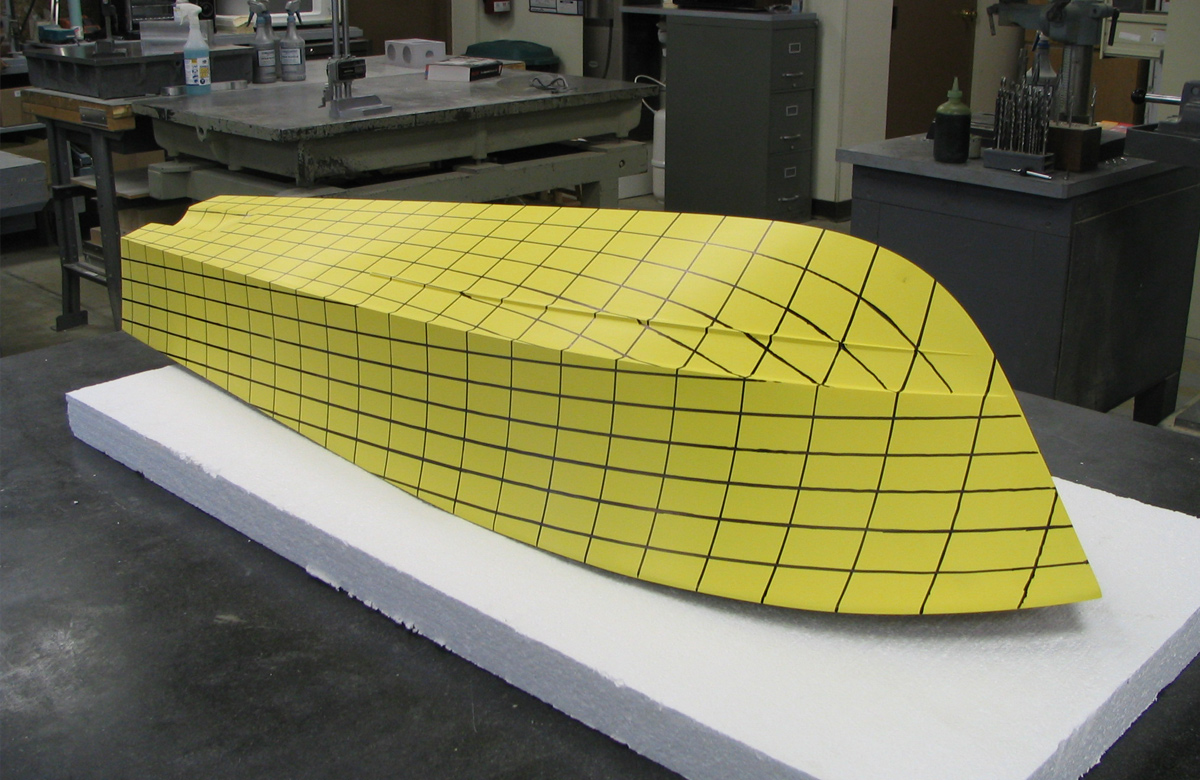

Case studies for validation and correlation will be presented to demonstrate the speed and accuracy of the program and to validate the method against model test data for a Series 62 test model, the United States Cost Guard (USCG ) 47’ Motor Lifeboat (MLB) parent model from the USCG systematic series of high speed planing hulls, a high speed prismatic planing hull with twist, and the United States Navy (USN) General Prismatic Planing Hull, which was the studied hull form in the 2018 Planing Hull Simulation Grand Challenge.

References:

1. “Resistance and Trim Modeling of a Systematic Planing Hull Series 62 (with 12.5°, 25°, and 30° Deadrise Angles) Using Artificial Neural Networks,” Radojcic, D., Kalajdzic, M., Zgradic, A., and Simic, A., Journal of Ship Production and Design, 2017.

2. “Power Prediction Modeling of Conventional High-Speed Craft,” Radojcic, D., Kalajdzic, M., and Simic, A., 2019.

3. “Small-Craft Power Prediction,” Blount, D. L., and Fox, D. L., Marine Technology, 1976.

4. “Examining Added Drag of a Planing Craft Operating in a Seaway,” Hoggard, M., SNAME, 1979.

5. “Performance By Design – Hydrodynamics for High-Speed Vessels,” Blount, D. L., 2014.

6. “Experimental Results for the Calm Water Resistance of the Generic Prismatic Planing Hull (GPPH),” Lee, E., Weil, C., Fullerton, A., NSWCCD, 2017.

7. “A USCG Systematic Series of High Speed Planing Hulls,” Kowalyshyn, D., and Metcalf, B., SNAME, 2006.

DLBA image

Share this article online:

HOW CAN WE HELP YOU?

FEEL FREE TO CONTACT US

DLBA Naval Architects

860 Greenbrier Circle, Suite 201 Chesapeake, Virginia 23320 USA

Phone: 757-545-3700 | Fax: 757-545-8227 | dlba@gibbscox.com

STAY UPDATED

SIGN UP FOR OUR NEWSLETTER

Keep your finger on the pulse of the latest points of focus in naval architecture and engineering: subscribe to DLBA’s concise monthly newsletter. Within it, we briefly describe and picture our latest projects and concepts. We encourage feedback and seek to have our newsletter spark conversation regarding potential collaborations and further advancements as we share our passion for the industry.